Energy and Costs Savings with Vapor Phase Soldering

Energy and cost savings in electronics production is easier than you think!

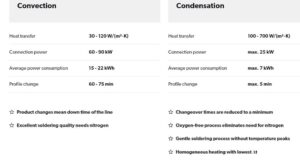

The largest consumers of electricity in SMT production are reflow soldering systems. This soldering process is used in many electronics production facilities worldwide, but it is a very inefficient method of soldering in terms of energy consumption. The extremely high-power consumption of convection reflow systems is caused by the inefficient heat transfer of air.

Vapor phase soldering uses liquid or vapor as a means of energy transfer so the entire pre-heating and soldering process takes place in a 100% oxygen-free environment, ensuring homogenous heat distribution without overheating of components.

Vapor phase soldering enables more than 20 times better heat transfer than air due to the liquid used.

This equates to a 70% decrease in power consumption when using an ASSCON vapor phase soldering system!

Find out more about the advantages of vapor phase soldering and ASSCON’s void-free vacuum technology by following the link above